Here's something I just got done and figured it would be a good tip/trick for the group.

If you have a piece of stock bigger than your band saw, sometimes there's a way to still get the job done! It's called ingenuity! lol

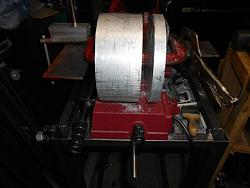

I needed to cut a slab off this 7 inch diameter 6061 round stock but my saw is a H.F 6 x 4 inch.

I came up with a plan and it worked great! It did take me 3 days to cut through itbut I was only working about 5 minutes at a time here and there because it was boring as hell. Total cut time was probably 45-60 minutes but that's a ball park estimate.

First I tuned up the saw getting it to cut as straight as I could. Then installed a new 10 tooth blade, removed the fixed front fence, the rear adjustable fence and put down a piece of metal plate. Then using angle blocks I made for my mill, I clamped the part down using a line I drew around the stock to line it up with the blade.

I would cut for a while and then rotate the part so it wasn't cutting through a lot of material. That actually speeds things up but also helped me to make a more accurate cut. I just kept cutting and rotating. Once you get an initial kerf cut, it's easy to just rotate and re-clamp. I kept the one angle block secured and never moved it until the job was done.

I have over 8 inches of space between the guides on my saw so I think this would work up to 8 inches. (not in a hurry to try it however)I'm just glad this is DONE!!!

Best part is with a square, it was only 1/16" off!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks