I have admired the curved top box made by Clark Kellog (Work — Clark Kellogg and wanted to make something similar

I've made a few curved top boxes with a jig (my Gen 1) that had a fixed radius. It works OK, but if you need to change the radius, you need to make new curved rails.

I wanted a fixture where I could adjust the radius of curvature and more easily adjust the height of my router.

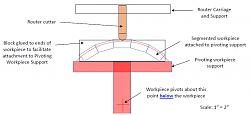

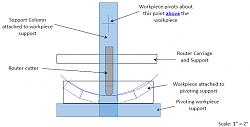

I envisioned the scheme shown below

The inspiration for this came postings I've seen form lutheriers for making guitar of other stringed instruments. The jig has a router carriage that allows the router to move back and forth (or left and right). The workpiece is screwed or clamped to a pivoting support that can swing about +30 with the router carriage in place. The same fixture is used for both concave and convex surfaces; the workpiece is mounted on the “top” of the pivoting support for convex surfaces, and on the bottom for concave surfaces. Similarly, the router carriage rails need to be moved from the “high” position for milling convex surfaces to the “low” position for milling concave surfaces. A ¼-20" micro adjuster on each end of the pivoting support allows for small increments to be milled on each pass.

I am still learning to use this jig, but it seems to work well for the pine, Douglas Fir, and red oak that I have milled so far.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks