Hi

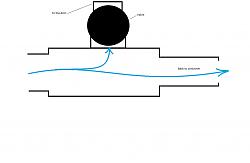

I made a cooling system to my second drill press too.

Actually, i can use same system with my mag drill also. Both hoses from fluid collectors goes to the same tank.

As a tank, i used old computer cooler. (Zalman reserator 1 )

I just changed bigger pump to it, used Eheim aquarium pump wich pumps 30 L/min.

Adjusted suitable flow speed for the cutting fluid directly from the pump. So, i don't need separate speed adjustment for the motor.

Collector is made from 1.5mm thick stainless 316 plate. Welds made with tig.

Used rubber cones as a feets, those are actually intented to be used to protect threads when sand blasting.

Feets are secured with strong epoxy.

Filter keeps hose open, its 3D printed and took 30 min to print, so its easy to change if it gets stucked.

Also hose clamp is printed. Magnet holds it in desired position.

Done:

Im going to upgrade my drill press soon, so made things easy to swap to the new one. Also collector is quick to empty when its unbolted.

Edit:

After consulting out cats i decided that its better to attach pan proberly to the drill.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks