For this conversion I was able to locate an early American made table that I will install a set of DROs on. When I am not able to find an American made table and must use an Asian table, there are items that need to be modified to bring them up to par. They are excellently described on Nick Carters site. These explanations are from that source. I have excerpted pictures and some of his write up. His site includes how to do the modifications on the leadscrew. This material is being used with his permission.

Source Cross-Slide Table Modifications I have made my comments in blue+

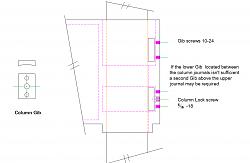

Gibs Not necessary but i use brass gibs whenever possible

The original gibs were steel and not suited to wearing in for that nice silky movement. I just made exact duplicates in brass. Over time they have improved the action noticeably.

Dial Gauge Control for Table Movement this is replaced by the DRO

With the poor leadscrew dials it was just about impossible to move the table with any precision. Since I wanted to drill accurately located holes, this was important. I tried mounting dial gauges with magnetic bases and arms but found it surprisingly difficult to get them placed just right. Constant headache. So here's my solution.

Photo 3: Y-axis Dial Gauge

Photo 3 shows the mounting blocks and rods installed to hold dial gauges for measuring table movement in the X and Y directions. This eliminates any uncertainty because of backlash, loose gibs or a sloppy lead screw.

Table Locks

Locating the table precisely is not much help if it's going to jiggle around whenever the tool hits the work. So locks are needed to make sure it stays put.

Photo 5: Y-axis Table Lock

Photo 5 shows the extra gib holes drilled and tapped to take the ball handled locking screws. Once tightened, these keep the positioned table perfectly stationary. Very accurately spaced holes can be achieved.

Thrust Bearing This improvement is almost a necessity

I wanted to try light milling on the drill press since I didn't have a milling machine at the time. Experiments showed that there was just too much uncontrolled table vibration. For milling, the table should be as jiggle free under movement as when locked down. Once the gibs are properly adjusted, the only other component allowing uncontrolled motion is the lead screw. I started with the thrust bearing where I assumed (incorrectly) all the backlash to be.

Photo 7: Original and New Thrust Bearings

Photo 8: Mounted New Thrust Bearing

The original was just a steel disc with lots of non-adjustable backlash determined by how (not very) close to it the outer sleeve was pinned to the shaft during manufacture. The new one carries a ball bearing and spacer so the backlash is determined by the precision of the ball/race fit. If I were doing it again, I'd make this block thicker and mount two ball bearings with a spacer between and some bearing preload. It's amazing how much play there is in a single ball bearing. I never thought of this until later but couldn't have done it originally anyway because I was fitting it to the original leadscrew and was limited to the thickness of the original thrust plate.

The new plate had to be larger in diameter to make room for new mounting holes outside the bearing recess.

Leadscrew and Nut This improvement is almost a necessity

The new thrust bearing helped but didn't completely eliminate the problem. The table could still be moved perceptibly back and forth. So I took the whole thing apart to have a look at the leadscrew assembly.

The original leadscrew has a 1/2-10 Acme thread and a very loose nut. The second nut in Photo 9 shows how I tried to tighten up this fit by adding screws to bear on the leadscrew. It was a half-vast fix and didn't really work. Making an adjustable nut for an Acme thread is problematic and, anyway, the cost of a 1/2-10 Acme tap is close to $100. So back to the drawing board.

Photo 9: Original Leadscrew Assembly

Here is the heart of all these modifications, a new leadscrew and nut. The leadscrew is 1/2-20 threaded rod and the thrust bearing end was machined completely on the Taig lathe. For some reason, at the time of making this particular part I made step-by-step photos which are in the appendix for those who are interested. The nut is adjustable following the practice of the Taig CR mill and is somewhat larger than the original which is shown for comparison. Also shown is one of two spare blanks made in case of a screw-up along the way.

Photo 10: New Leadscrew and Nut Assembly

Dials and Handles Nice improvement but not necessary with DRO

The original dials were intended for a 10 pitch leadscrew and were too small. The new ones have 50 divisions to suit a 20 pitch leadscrew and are the same size as the new thrust bearing carrier.

Photo 11: Original and New Dials

Photo 12: New Dial Mounted

The dial carrier was made the same length as the original pinned spacer. The new dial is held in place by a circle clip which is bent and rides in a groove wide enough to let it press lightly on the dial so as to damp its rotation.

The increase in leadscrew pitch means more turns per inch table travel so rotating handles ease the wear and tear on fingers.

Again I would like to agknowledge that the above post is located @ Cross-Slide Table Modifications in its complete form. The details for makeing the Lead screw are at that location.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks