Hi,

Here is something maybe very specific, but that could be of interest for CNC mill owners.

The goal is actually to adapt a laser head instead of the spindle in order to perform some engraving, or cutting or whatever...

There are different challenges, hardware and software.

Here I'll address only the hardware part.

The main difficulty is to trigger the laser diode by the CNC controller board, and not only just powering it on or off, but also

controlling the optical power.

Most of the CNCs (at least most of the hobbyist grade CNC's) control the spindle using a VFD drive, and two or three outputs are used from the controller board:

- 1 or two digital output to command the CW run or CCW run

- 1 analog output providing an anlog signal between 0 and 10V for scaling the spindle speed between 0 and its max speed.

On the other hand most of the laser heads use a single PWM signal to set the power of the diode.

0% duty cycle meaning diode off, and 100% duty cycle meaning diode on, with all intermediate settings possible.

So, in my case, I was about to make myself this 0<10V DC to PWM TTL converter, but searching what was already available, I found a small conversion board that did exactly the trick:

The name is "Fasizi 2 modules PWM de 0 V à 5 V/0 V à 10 V de 0 à 100 % de tension de signal PWM" on French Amaz...

It also requires an external 12V power supply, for that, at least for the moment, I decided to use my usual bench power supply .

Now I had to decide how to enclose this.

I wanted to have it removable, as the main usage of my machine will keep for milling.

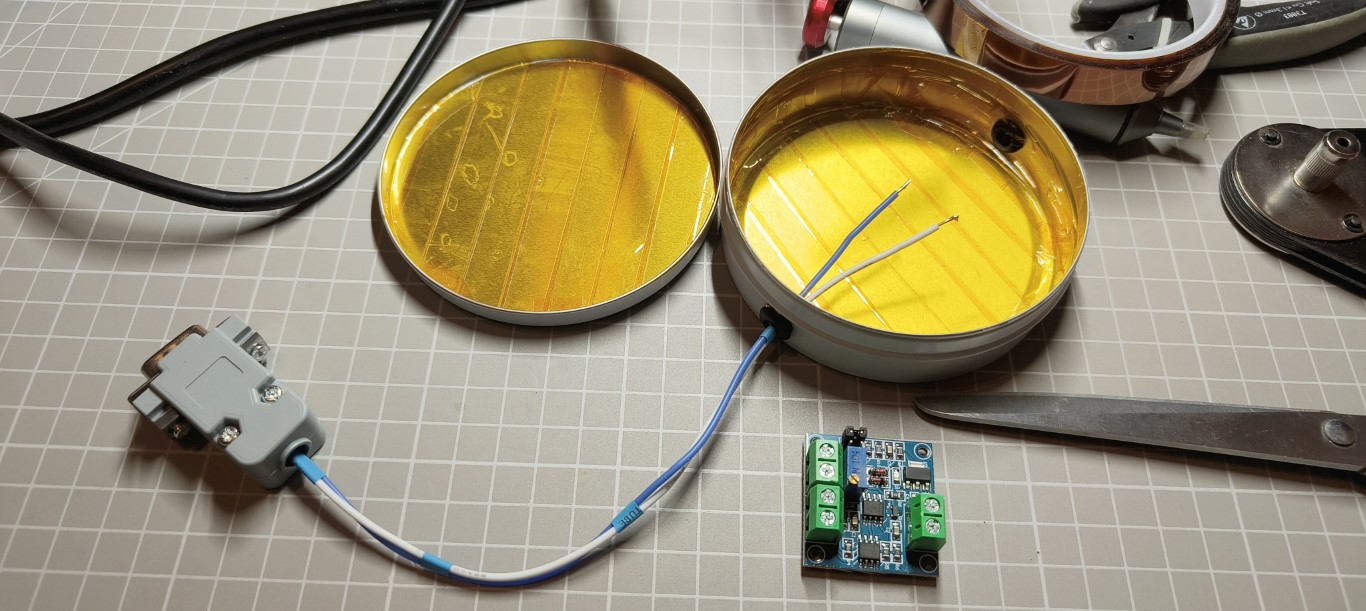

I looked around and decided to go with this small round metal box (cosmetic cream container).

You'll see later why this turned out to be a good choice.

First I drilled a couple of holes, (using a stepped drill) and inserted some plastic rings to protect the wires that will go through :

Next I had to insulate the inside of the box, I used Kapton tape to do this:

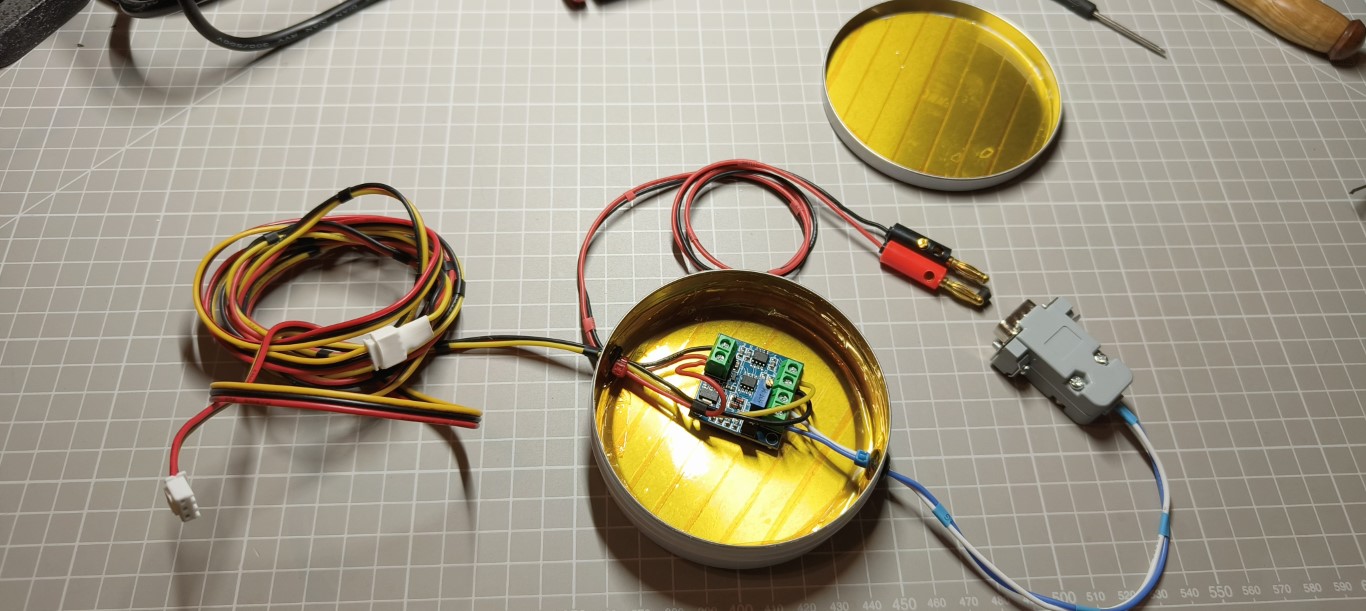

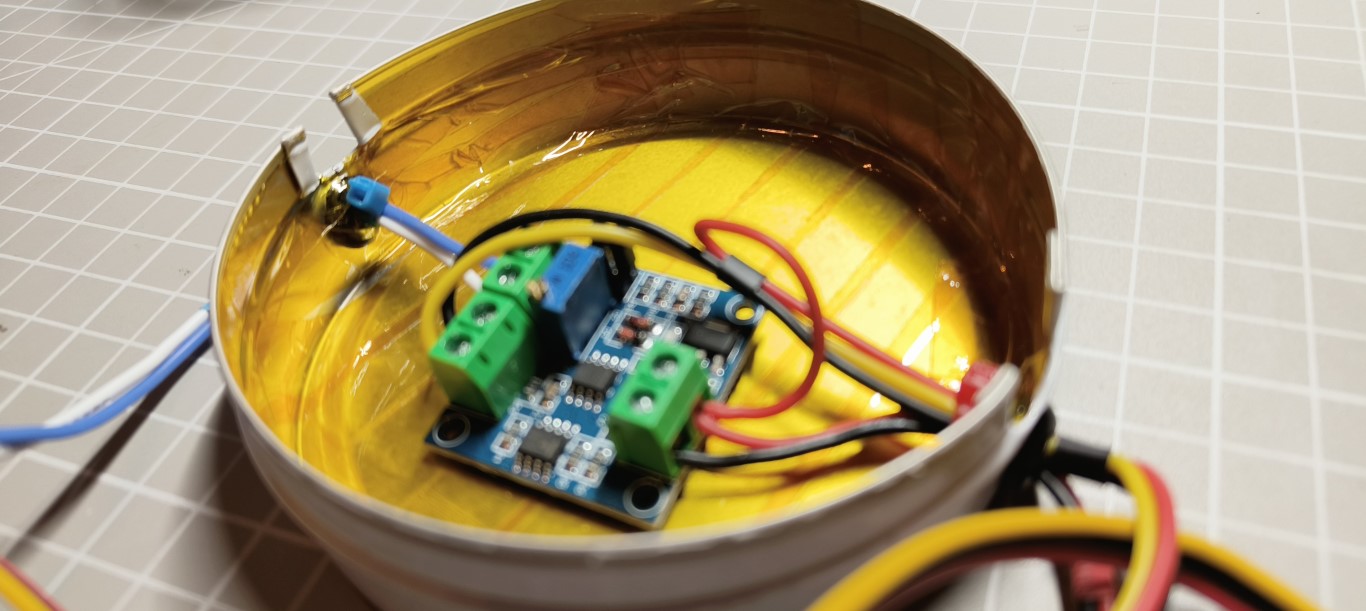

Here is everything wired :

On the left, the long cable that connects the head : GND, 12V, PWM signal.

On top the 12V input power (banana plugs to fit my bench top power supply)

On the right : a DB 9 connector that plugs into my CNC controller board (CSMIO IP/M from CsLab)

And then I realized that I had enough room yet in that box, and I could tidy up the wires in it when not used.

I improvised these notches on the edge of the box, to let the wires re-enter the box.

And here is the complete assembly:

On the right you can see the laser head.

And here is the beauty of the thing : when not in use, everything goes back to the box :

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks