As anyone with a classic motorcycle knows achieving a smooth clutch action is difficult, this is not always due to the clutch itself even when set up correctly but more to do with the pushrod actuation.

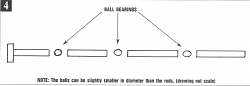

The gearbox main shaft has a gun drilled bore which is left as a drilled finish, when pressure is applied to the ends of the push rod it will bend and rubs in the rough bore surface resulting in a sticky or jerky action, close inspection of a used one will confirm that this has been happening as there will be score marks on the rod.

Fortunately there is a simple remedy as written by Don Morley of trials fame in an article which can be found on Hitchcocks website. Hitchcocks Motorcycles - Technical Notes under article 5, the cut ends should be hardened and polished and as this is usually drill rod it is easily done.

I can testify that this mod makes an enormous difference to the feel of the clutch lever, the weight is still the same but the action is nicely smooth and I now do this mod on any classic that I work on.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks