This is a tip that should be of interest to many home and professional machinists, at least those who machine aluminium alloys.

Most home shops do not use flood cooling, instead machining is done dry, brush dabbing, drip feed or water based misting. Maybe just a dry air blast. It is not uncommon, even on CNC machines with flood coolant, for aluminium to build up on milling cutters and other cutting tools, that increases heat production and the situation deteriorates very quickly, with the build up accelerating rapidly. At worst this results in broken tools and at best you end up with a tool clogged up with aluminium which in many cases can be very hard to clean off by mechanical means. This tip shows a very easy way to remove such build ups completely.

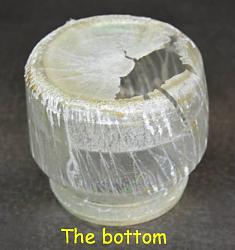

Click for full size.

It is as simple as mixing some Caustic Soda NaOH granules in water. I do not know if there is an optimum concentration but I usually mix it until the solution feels quite soupy. I think that it is just a question of; "The higher the concentration the quicker it works". Then just drop your clogged tools into the solution. If I do this last thing at night then the tools are as clean as a whistle by morning. This works on both HSS and carbide equally well. If you leave the tools in too long they will come out with a light grey coating but this just Aluminium out of the solution and wipes off easily. To extract the cutters from the solution I use a magnet on a stick wrapped in a plastic bag and wash it all down straight afterwards.

WARNINGS

Add the caustic soda granules to the water slowly. Do not add water to the granules as heat is produced in the mixing and may cause almost instant boiling with explosive like force. It is a good idea to put your jar in a bucket of cold water to help keep it cool and contain the solution should the jar break. I do this in my workshop sink. I always add the NaOH slowly and monitor the temperature rise. Once the solution has cooled it can be handled without problems, but remember that is corrosive so wear gloves and eye protection, wipe any spills with water.

The second warning is from my own experience. Unless you know more about plastic/caustic soda compatibility than I do then do not use a plastic jar. I did that once and after use I simply put the lid on and stored it for any future use. Some months later when I went back to it all I had was a corroded jar as you can see in the photos below. I do not know what type of plastic the jar was made from. I have never had this problem with glass jars. Glass coffee jars seem ideal. Pyrex would probably be an additional safety factor because of its temperature change tolerance.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks