Hi folks

eBay has been a bit of a goldmine for inexpensive engineering items recently, which is great, because I run on very meagre budget for this game and some of the items I've managed to aqcuire would normally be well beyond me without some serious saving.

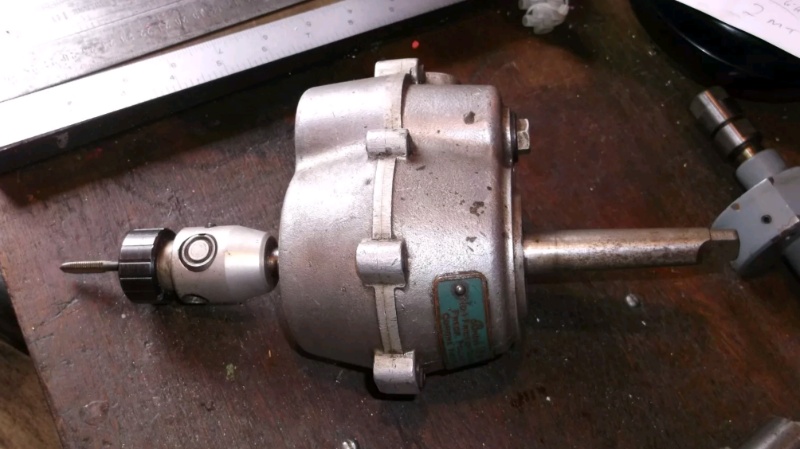

One such is a Pollard auto tapping head, which I managed to grab for a shockingly low £37 (shipping included).

I had a hunch there would be a catch as such expensive items don't usually go for so little without one. The catch with this one turned out to be the head, which was totally filled with chip infused crud and was jammed closed with the last used tap still in it:

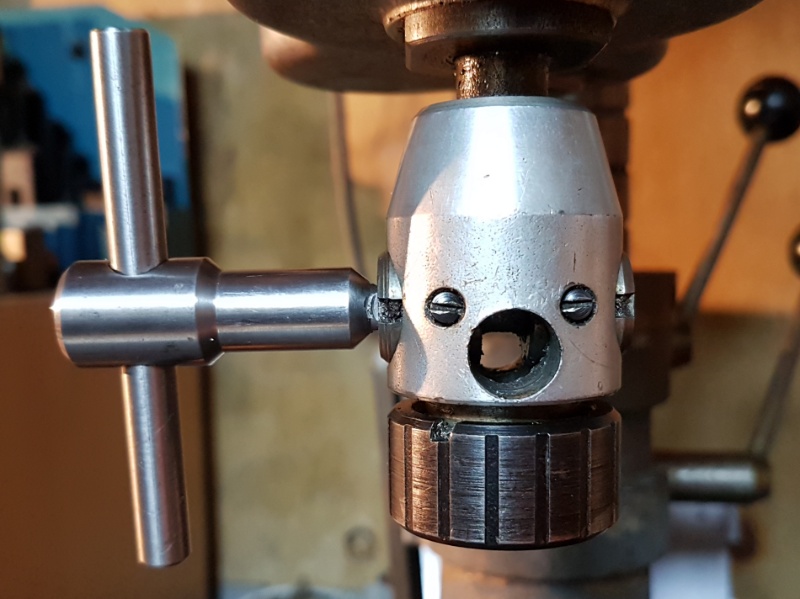

Now I may be new to the engineering game but it didn't take me long to work out how the head was supposed to be operated and the issue largely revolved around the clamping mechanism, which uses something akin to a chuck key to close the clamps onto the tap flats and it's two tiny set screws. I must apologise at this point as I didn't take many pics, this was all new territory for me and I wanted to be focused on not screwing things up.

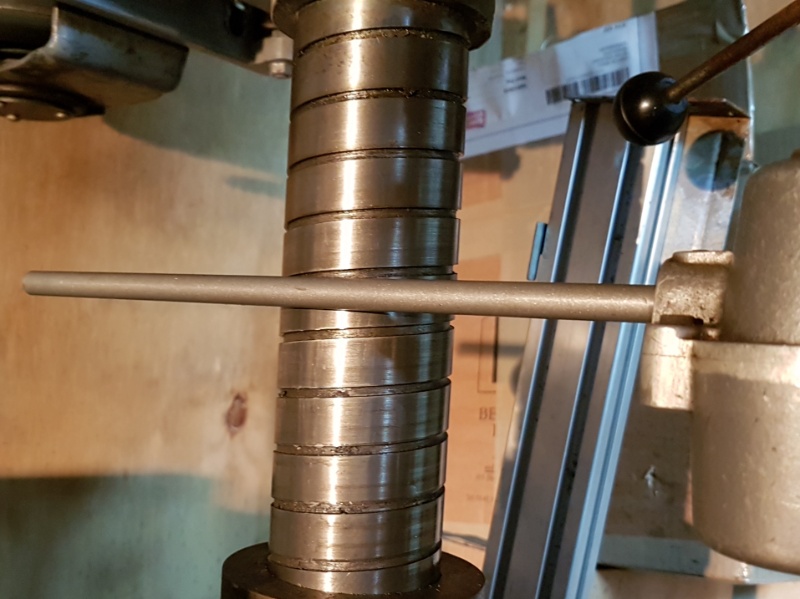

Unfortunately the head didn't have the clamp key with it, or the catch bar (? Don't know it's proper name but its the bar that stops the main body from spinning while your tapping), so I set about making both of them while I let the head soak in some WD40.

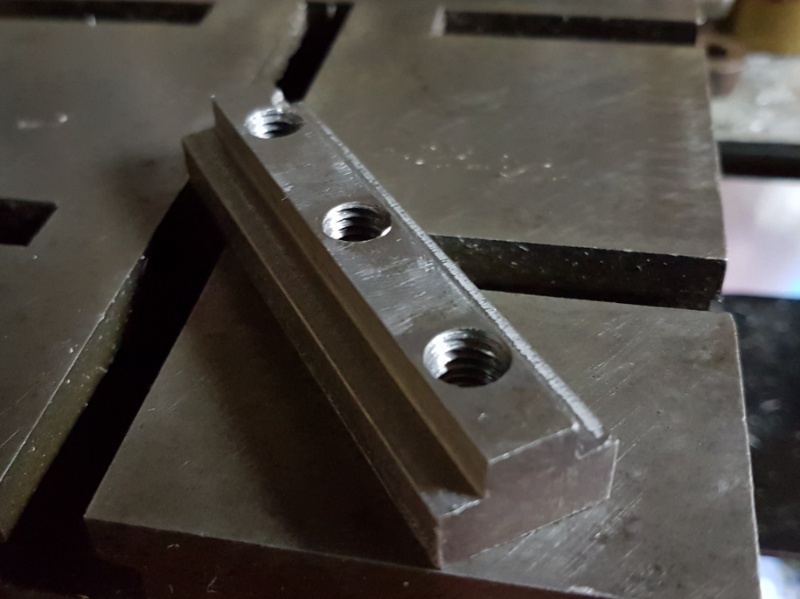

The catch bar was made from a piece I chopped off a treadmill frame and took seconds as it was just a shade oversize and was already coated, which is a very close colour to the head so I just got lucky with that one:

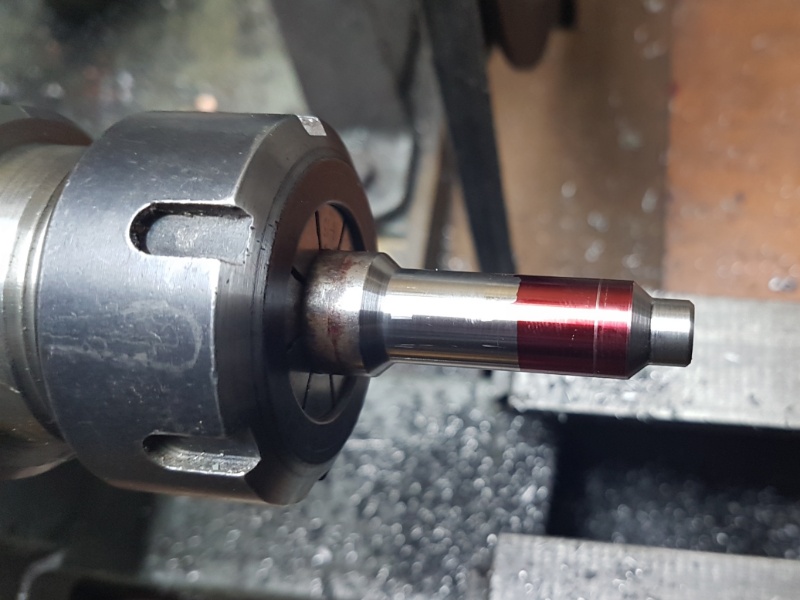

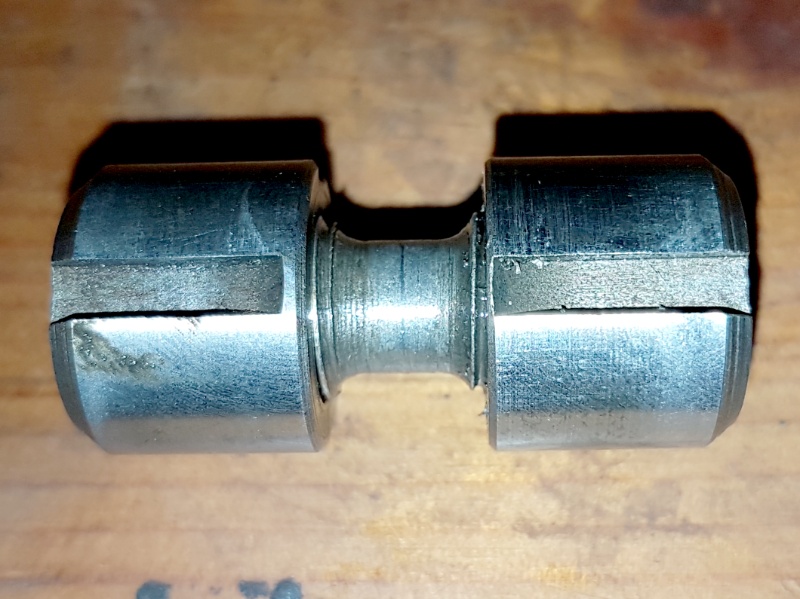

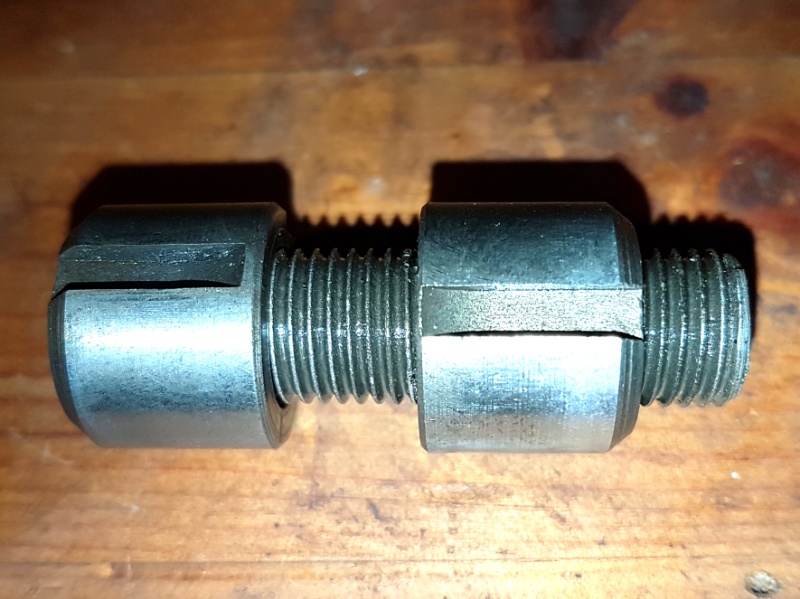

The key on the other hand was entirely the opposite and represents many hours on my part spent working out setups and playing musical chucks with the dividing head and lathe for the various turning, drilling, tapping and milling operations performed while making it:

I actually went too deep with the first set of flats in the pic above, so I turned the end off and started again. As such it ended up being a bit more stumpy than I'd intended but it's a perfect fit now so I'm happy as Larry with it

I was then able to use the key to aid in the repair of the head, the only part I couldn't save was a twisted and broken spring in one of the three jaws in the head but other than one slightly shorter spring now, everything works as it should, though I made one last modification of my own, which was to cut the tang off the shank so it would fit into the spindle of my Dore Westbury mill, which is a little on the shallow side for standared MT2 tapers.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks