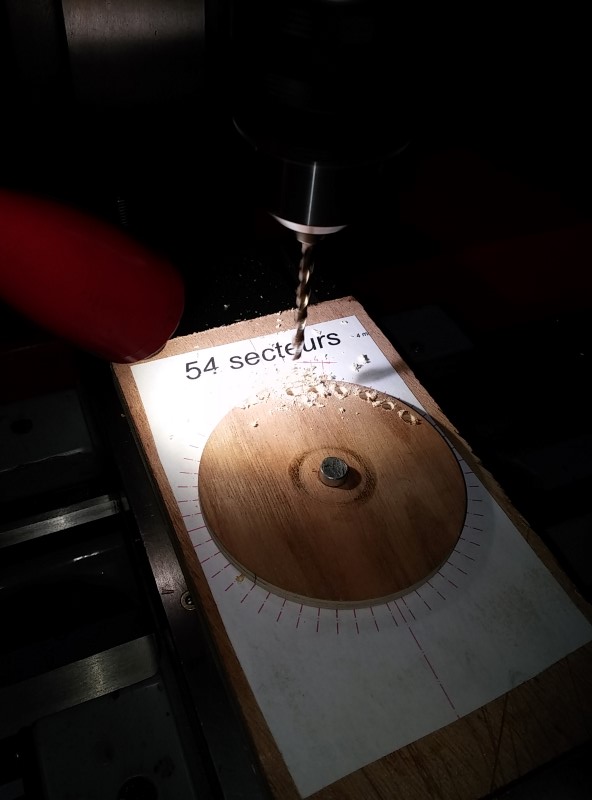

I wanted to make my own rotary encoder, using quadrature IR Led emitters and receivers, so I needed to make a small disk with 54 holes in the perimeter. (54 because of some design constraints)

I don't have any rotary table, and the angle 360/54=6.66° is quite odd and does not suite my index plate on the lathe.

In such situation, my solution is always to rely on my inkjet printer and my favorite CAD software.

It is really amazing the accuracy we can achieve with a simple inkjet printer, and one big quality of this method is that you never accumulate errors.

Even if a single stroke can have maybe 1 or two tenth of a millimeter of error, the error is not repeated as if you were using for example a caliper to mark from point to point.

Here is how I did:

you can notice the small pencil index on the edge of the disk, which I align successively on the purple spokes of the drawing.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks