Do you have a worn chuck that is only gripping on the back of the jaws, here is a way to fix it.

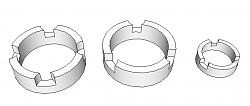

This simple tool will do the job if your chuck has hardened jaws, by gripping the jaws by the front only (where most work is done) while allowing a grinding wheel access though the length of the chuck.

My 50 year old 5 inch 3 jaw will grip a 5 inch long test bar with the same run out at the end as at the jaws (usually within a thou) after this treatment.

You would think that working in a tool room everything would be looked after but sadly not so, I have seen chucks tightened with extension bars and metal being torn out of 3 jaws when 4 jaws should have been used (laziness is the common culprit), this obviously renders them useless for accurate work unless the jaws are ground true. I am not suggesting that anyone here would do these things but maybe you have an old chuck that could be reclaimed.

On the subject of trueness of 3 jaw chucks I have used a method which is is a little unusual and may not meet with everyone’s approval. I have turned the backplate register -.008 thou to allow a small amount of movement for final adjustment if needed, after which the mounting bolts are tightened, I can almost here the disapproval but I can say I have never had the chuck move while in use, indeed all faceplate work is clamped so why not a chuck. If you don’t like this idea I find that a few taps with a soft drift on the offending chuck jaw to settle the scroll before final tightening will often do the trick.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks