I scored a bunch of assorted bits of 80:20 style aluminum extrusion off of ebay, and am using one piece as the basis of the table saw fence I'm making to replace the horrible plastic thing it came with.

You need some tee-nuts to slide into the grooves to attach stuff to the extrusion, and when my local Ace didn't have any, like a sane person I just ordered some online and waited a few days.

..oh wait a minute, this is me...

So I communed with the connectors aisle for a bit and came up with a bunch of carriage bolts that looked good for a fit, if I ground some of the heads off...

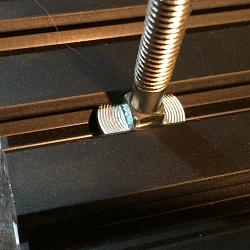

After hand filing one, laboriously, for a proof of concept, and to confirm it fit:

I marked out a square on a piece of ¾ x 1/8 steel, set in the correct amount for the fit, drilled it out, spent a half-hour looking for the blades for my jewlers saw, then five minutes staring at it on my tool rack swearing "I know it's here somewhere!!", then a bunch of time filing a square hole:

(note the custom designed filing post (crowbar) bringing the work up to eye level)

Drilled and tapped a hole for a handy screw, and made a top clamp out of another piece of the same bar stock.

Voila! Clamp in the bolt, put the thing in my vise, and file or grind to the edge of the jig and pretso: tee-bolt.

Now I can go spend sixteen cents at Ace and five minutes with a file for my tee-bolts.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks