I personally do not use indexable carbide turning inserts, not that I have anything against them nor have I not used them in my 44 years in this trade, I just prefer cobalt high speed steel over carbide inserts, I do however use brazed carbide tipped lathe tools for hard steels, I have 25 -30 solid carbide end mills and use them religiously.

A couple of weeks ago I was at a yard sale and I noticed five boxes of these tin coated 60° triangular inserts lying on a table that were marked $1.00 a piece and labeled TCMT 3/8” IC (inside circle), without any thinking I gave the lady $5.00 thanked her and left, so with these 50 triangular inserts I decided to make a set of Turning, Facing and Chamfering Tool Holders.

The straight turning tool holder was made with a 1/4” left hand offset so I could work close to the chuck, the inserts seat is milled in the holder so that the insert has a 3° inverted point for turning up to a shoulder and then squaring the shoulder by turning the cross feed on the lathe out, the 45° turning and facing holder is milled so the cutting edge of the inserts are at 45° to the axis of the lathe.

The tool holders were made from O-1 tool steel hardened and tempered; the insert holders were only ground flat on the bottom after the heat treatment, the rest of the tool holder was left blackened from the heat treating process to act as a rust inhibitor, the seats where the inserts lay were then ground parallel to the bottom of the holder.

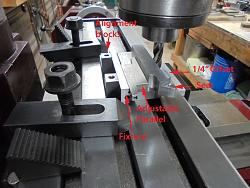

I made a special fixture to hold the tool holders so I could machine there edges, all this fixture does is acts like a shim to lift the work piece up off the mill table so I can machine the edge of the work piece without cutting into the mill table, the fixture also has a shoulder on it to locate the edge of the work piece, this fixture was also made from O-1 tool steel hardened and ground, I have future uses for this fixture not just a one time deal.

Below you will find some photos of the machining process along with the turning tool being used to turn down a planer shaft.

As always thanks for looking and happy machining

Doug

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

PJ

PJ

Bookmarks