I recently saw an ad for a tap wrench bubble level and thought these would be very useful and easy to make for the shop. The bubble levels are used to ensure the tap is starting square to the part and staying in alignment to the pilot hole during taping. The alignment process assumes the part is already level.

I used T6-6061 aluminum 0.750” and 1.0” diameter rods to make the bubble level cases. The 0.545” diameter by 0.33” thick bubble levels are available through Amazon.com (14mm Circular Bubble Spirit Levels) and eBay. I checked the bubble levels on my level surface plate and these were indeed level and the thickness of the levels are exactly the same all the way around. This is important because the levels fit against the machined inside bottoms of their cases and parallel to the case bottoms. I made two bubble level cases with slip fits over the ends of a small (0 to #8 tap) and a larger (#4 to ¼”) T-handle tap wrench. In addition, I made one of the bubble level cases with a rare earth magnet on the back. This allows the level to be used in many applications in the shop.

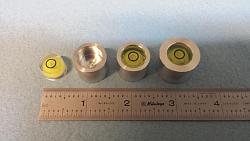

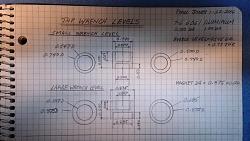

I included the plans, photos of the tap wrench bubble levels, and an example of the level guiding a tap wrench. These plans are kept in a spiral bound grid paper notebook that I use for sketching tool ideas.

Close-up view of tap wrench bubble levels with and without magnets

T-handle tap wrench without bubble level

T-handle tap wrench with bubble level

Level case ready to install bubble level and secure with Loctite 680

Large and small cases for T-handle tap wrench bubble levels

Machining and boring the T6-6061 aluminum cases to 0.547” dia. to exactly fit bubble levels

Plans to make the T-handle tap wrench bubble level attachment

As you can see from the photos, these are very useful and easy to make. I am sure the one with the magnetic backing will be useful in other leveling applications around the shop.

Thanks for looking, Paul Jones

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks