Hi All

I am currently in the process of motorising my bead roller and thought I would also do the same to my slip rollers and ring roller using the same motor by simply bolting which ever tool I intend to use to a table and using vee-belts.

The issue I have is the slip rollers were made along time ago and I didn't consider ever powering them until now. There is currently a square drive which an old vice handle fits to. This doesn't allow enough round shaft to fit a vee-pulley to. So I decided to make an adaptor to drive of the square and locate of the 20 mm diameter shaft but allow enough room for a 1-3/8" 2012 taper lock bush to fit with a 1/4" keyway.

So I thought I would share with you all how I broach square holes on the mill using an indexing head and a cutter ground like a D-Bit.

The first operation is to turn the adapter and bore/Drill a hole to finished sized square this is sized across the flats (A/F).

A D-Bit is then ground from a round piece of high speed steel (HSS) to half its diameter.

The component can then be centred over the indexing head on the mill. The tool can be held in a chuck and the machine placed in low gear to prevent the spindle from rotating. Even better if you have a brake.

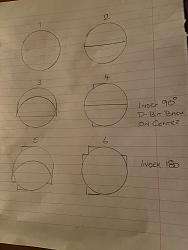

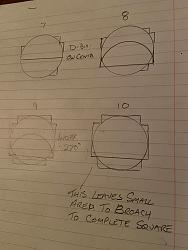

It is now a case of moving the quill of the machine up and down in conjunction with one axis taking very small cuts. The two photos below show the procedure for cutting the square.

Complete setup on mill

Process for cutting

Cutting square

Finished hole to size

Square drive shaft and fitted adaptor

I have used this method for cutting different size squares and have made several size broaches. The large one was made from mild steel and a piece of parting off blade silver soldered to the mild steel shank . This was used to cut a square slot in cast iron on the axle boxes of my 3" scale Foden steam wagon.

Square cut and gauge piece used to check fit along with the D-Bit

This method works really well and is very accurate, Like everything there are some drawbacks The deepth of square is limited by how far you grind the tool and the longer the tool more flex so more patience is needed. Plus side very cheap to make and almost any size can be cut rather than buying expensive square broach which will only cut the size it was intended for and the shape. Using the D-bit hexagons, slots etc. can be cut.

I hope you can make use of this post and thank you for taking the time to view

The Home Engineer

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks