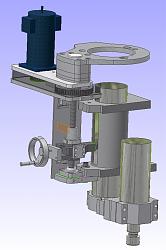

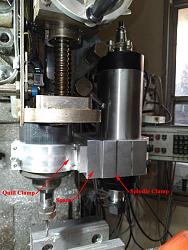

I have converted my Bridgeport Mill to a 4 axis CNC machine. It is a belt drive J-Head machine, and the maximum spindle speed is 2720 RPM. This is adequate for many jobs, but when engraving or cutting with small diameter end mills, it is not possible to get the SFM high enough, and the feed rate must be limited to a snails pace to avoid breaking tools. I have wished for higher speeds, and have now found a solution. I purchased a high speed water cooled spindle on Ebay (2.2 kW, 24,000 RPM maximum) and mounted it onto my existing quill. The new spindle travels up and down (Z-axis) with the original quill. It is offset about 5 inches on the X-axis from the center-line of the Bridgeport quill, and can be installed quickly when needed. It does limit the Z-axis travel a bit, but that is not an issue for many parts I make.

The installation requires two new parts, in addition to the spindle kit which includes the spindle motor clamp. A quill clamp was fabricated and bored for a close fit onto the Bridgeport quill. It is split and has two 1/4-20 socket head screws to tighten in place, plus a third 1/4-20 screw to allow forcing the clamp open for easier installation. A spacer plate was fabricated and drilled to mount onto the quill clamp, and to accept the 8MM mounting bolts attaching the new high speed spindle motor. The spacer plate thickness is adjusted to provide clearance between the new high speed spindle motor and existing Bridgeport hardware. The manual handle is removed from the Bridgeport when using the new spindle.

I plan to post more details on the CNC conversion at a later date.

CAD Model of assembly

CAD Model of Quill clamp

CAD model of spacer

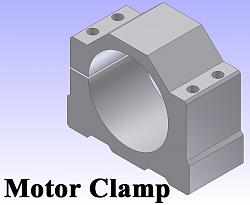

CAD model of high speed spindle clamp

TAGS: CNC, Bridgeport, Milling Machine

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks