I love using my Grizzly track saw but it has one or two kinks that needed improvement. One kink was the clamps that were provided to hold the track in place on the wood being cut. Since these clamps attach to Tee Slots on the bottom of the track, the clamps are below the work and usually below one of my folding work tables, holding the work and track in place on it. So, tightening and loosening them is somewhat awkward. And the handles on the clamps are just round wood with a glossy paint that does not provide much grip.

Space under the top of the folding work tables is cramped with the mechanism for operating the vise like top so I did not want to increase the diameter of the clamp handles by much. I guess that is why they made them so small in the first place. But I wanted a better grip.

After looking around the shop, I found some scrap electrical wire, about 14 or 18 gauge that had a somewhat rubbery insulation on it. It would definitely provide a better grip than the glossy, painted surface. I drilled a couple of holes in the wood handles and cut two pieces of the wire to be wound between them.

You can see the original clamp on the left. On the right is a second one with the wire grip installed. In the center is the coil of wire that I used.

I drilled the two holes a bit larger than the outer diameter of the wire for an easy fit. Some super glue in the hole secured the end of the wire and after wrapping the first turn I added more super glue all around the junction of wire and handle. I continued wrapping and adding some super glue every five turns until I got to the second hole. After each five turns were wrapped but before the super glue was added I made sure that those turns were tightly packed against each other. At the end with the second hole I pre-shaped the end of the wire to fit into the hole and then unwrapped one and a quarter turns and added super glue around the wire-handle junction and a drop in the hole. Then that last turn was completed and the end inserted into the hole. Some scotch tape held everything in place until the super glue dried.

Now they are a lot easier to install and remove.

Check out my plans ..............................

Quick Change Tool Post For Lathe

Very repeatable tool position; Change tools with a single hand and no wrench.

No quick change tool holder is faster.

Magnetic Soft Vise Jaws

Quickly install the perfect jaws for the task at hand.

Measuring Tape Dispenser

Handsome appearance. Dispenses accurate lengths of tape.

Illuminated Dropped Parts Finder

Unique use of light allows small parts to be easily found on dirty floors.

Adjustable 3D Printer Reel Stand

Inexpensive, easy to make, adaptable for any reel size.

Universal IR Remote Receiver

Provides control of your devices with any IR remote (TV/DVD/BluRay/etc.)

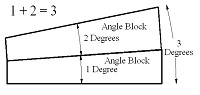

Using Angle Gauges for Any Angle

How to set up any fractional angle using inexpensive angle blocks

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks