One of your most useful tools is your electric drill. But all it is is a hand-held motor. Like a Dremel, its real utility descends from all the accessories it can power. Nevertheless, there are jobs where bringing the work to the tool is better than bringing the tool to the work. Compare sharpening a chisel using your electric drill to sharpening it on a grinder bolted to your bench.

So, it occurred to me that a motor bolted to the bench would be a really handy tool. Fixed in place, hundreds of accessories and more power than any electric drill could deliver.

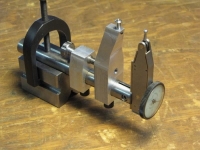

So, I bought a reversible motor, bolted it to my workbench with the shaft projecting over the edge, wired it for reversibility and mounted a 3/8" Jacobs chuck to it using an adaptor I made on the lathe...

Equipped with wire brushes, sanding pads and drums, grinding wheels, and polishing buffs it's become one of the most-used tools in the shop. Variable speed would be nice but this was all done in the days before treadmill motors appeared in every junk store. Actually, the 1750 RPM isn't all that bad a compromise for most tasks. The reversibility is especially handy when wire brushing. After some use, the bristles tend to get bent and, as a result, wipe more than impact. Reversing the motor undoes this effect and gets them cutting again. Often, when grinding or sanding, holding the work for one direction of rotation can be awkward while, with reverse rotation, it becomes easy.

The chuck is key operated. With larger wire wheels, the sharp bristles hurt your hand as you attempt to use the relatively short, tiny chuck key. I knocked the rod out of the key, fitted a longer handle over the key body, pinned the key in place with a pin through the handle and the original handle hole in the key and stuck the original key handle on the end of the long handle. The result is a long reach chuck key that keeps your hands clear of scratchy tools held in the chuck...

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks