A bench block is an exceedingly handy tool. For those unfamiliar with it, it is an upside-down cup shape made from steel. The top is festooned with holes of varying size and a large V-groove through the central hole. It has a multitude of uses, limited only by the craftsman's imagination, but one primary use is to remove pins from axles, gun parts, etc. by supporting the part on the block over one of the holes and driving the pin out with a pin punch. The pin is then handily trapped inside the hollow body of the block so you needn't chase it around the swarf on the floor.

The first figure shows the block in the foreground with some accessories arrayed around it. The circular wooden piece is sized to fit into the bottom of the block and is held there by two small (1/4" OD) neodymium magnets glued into its periphery. The larger circular piece is bolted to this assembly. More on that later.

Behind the block is a wooden carrier with an assortment of mini-anvils of various shapes. One of these is shown mounted on the top of the block. They are used for various tasks including both shaping and shearing thin metal. Also, on the wooden carrier is a brass soft anvil sized to fit the central hole of the block. You can see it in place on the second picture. It's used when working on material that might fair poorly if it contacted the hardened steel of the block. For even gentler work, anvils can also be easily turned from aluminum or plastics. On the left are the components of a simple clamp (discussed below)

This photo shows the wooden base fitted to the block and the block inverted. This forms a nice wooden surface stabilized by the weight of the block which is used when working with knives, chisels, etc. that would be dulled by a collision with the hardened block. As mentioned, this work surface is bolted to the structure that locates it on the block so it's sacrificial; if it gets too chewed up, it's simple enough to make a new one and bolt it in place.

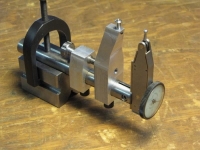

This photo shows the clamp in use. The aluminum fitting on the threaded rod fits into the central hole of the block from below and allows the height of the threaded rod to be adjusted. In this view, the block is shown sitting on its wooden base. As can be seen, the projecting edge of the sacrificial piece provides space to clamp the whole structure to the work table if so desired. The wooden base is also handy as a cap for the interior space of the block, allowing the storage of some of the accessories there.

I'm currently working on an arrangement to clamp rods into the central V-groove but that is on a back-burner because I have a variety of V-block pairs that can be used for that purpose.

Think about adding a bench block to your workshop armament. If you work on delicate stuff, like expensive firearms, note that nylon and plastic bench blocks are available; Brownell's has the former.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks