Everyone should know by my avatar that I have in the past done quite a lot of line boring on equipment. Using line boring machines that cost several thousands of dollars to a simple machine using a Do-More Virsi-mill a boring bar and a couple of bearings as my avatar suggests.

Several years ago, I made a boring bar to bore out and excavator link on my lathe

The other day a customer dropped off a Cat 420 backhoe badly in need of new main boom pivot bearings the locations were worn so I made a complete line boring machine for the task Starting with modifying the old boring bar I had previously used by turning one end down to accept 25mm bore bearings, then made a feed tube by threading a 2.375" 12 TPI thread along its length, and made a nut to serve as the feed nut.

Once this was done, I welded a pair of flat bars with a hole in one end of them to one of the guide bearings I had made for the old boring bar 2 3/8" bolds would bolt the feed nut to the guide bearing then by rotating the feed tube the boring bar would be fed into the locations while the cutter bored them to size. to drive the line bore bar I selected a steering shaft from a Truck I have been paring out since the shaft had universal joints on either end, and a 6" telescopic spline To power the machine I had a 36VDC gear reduction motor salvaged from an old Tenet floor scrubbing machine. To power the motor, I first started out using may battery charger at its highest setting this worked but without a battery in the circuit I wasn't receiving the constant current I needed nor the RPMS I wanted as I was only able to supply around 18VDC, So I elected to forego the charger and used 2 group 31 truck batteries in series giving me a full 28 volts at full charge. this produced around 250 PRM cutter speed while hogging the cutter through the welded bores

One nice thing about the machine is if using it in the field most heavy equipment has 24v systems a pair of jumper cables is all that is required to run the machine I made 6 passes through the 2 bores over a period of several hours and when finished the batteries were still at 90% charge

I widened the notch with a grinder to accept a 1/4" bar to fit the keyway of the motor

I lengthened the slip tube to take full advantage of the shaft spline

I drilled a sleeve to adapt from the 3/4" motor shaft to the 15/16" of the splines on the u joint ends

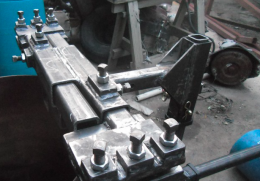

motor and drive shaft

view of cutter

feed disconnected to check cutter

feed connected rotating the feed tube was nearly effortless

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks