still a bit of a work in progress, but I made these in the hope of balancing a wire wheel which is causing my grinder to vibrate.

Idea is to have a groove in which some ball bearings are free to rotate and come to rest at the point of lowest effective mass on the wheel, thus balancing it. Well, that's the idea anyway, not quite there yet.

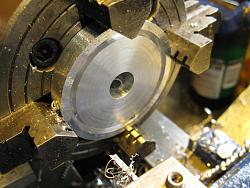

blank turned and drilled

reamed to 0.501 or so, slip fit on the arbor. Face relieved so that the arbor only contacts the wheel at its periphery. Not 100% sure why this is necessary, but that's how the original ones are made so..

first arbor parted off

one set done - the other set was already made from a previous grinder

mounted, centered and a groove trepanned for 3/32 balls (for my mtb pedals)

both sides done, with the bearing covers also parted off from the same blank

test fit

balls loaded. After the 1st try, where nothing happened, I cleared out the grease. Still nothing, so I added more balls - 25 on the wire side.

stone side. This side really didn't need any balancing, ran really smoothly without any balls. Figured I'd add them anyway in case the balance changes over time with wear

wire wheel side

the arbors did help reduce vibration a bit, but not eliminate it completely. I'll be cutting the groove to 2x ball width to allow the balls to bunch up to see if that improves things. If not, I cut the groove deeper and use larger bearings for more mass. I'll report back with my findings!

here's a great article about both the physics and another machinist's trials and tribulations with balancing grinders

metalmagpie's balancing arbors

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

and larger postal for big stuff. Wire wheels will continually change as they shed but your ball bearings should be great for that!! Also maybe a lighter lube than grease like 3in1 or such. Just thoughts.

and larger postal for big stuff. Wire wheels will continually change as they shed but your ball bearings should be great for that!! Also maybe a lighter lube than grease like 3in1 or such. Just thoughts.

.

.

Bookmarks