Originally Posted by

metric_taper

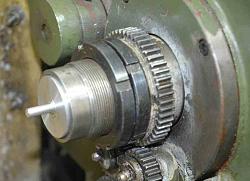

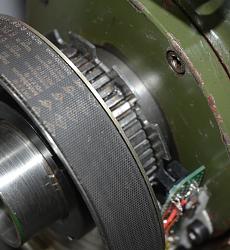

Tony, I have a 1976 Jet 1024 lathe. It was made in Taiwan. The head stock is similar casting as well the sight glass is the same. I found when I pulled the spindle many years back, that there was only a single hole going from the oil reservoir to the bearing (the hole level with the normal oil level). The sight glass is a front plug for this reservoir. This hole was straight back to the roller bearing. So the sight glass could show oil at the lower line level, but the bearing could be dry. So I modified both the front and rear bearing reservoirs, by drilling a 1/8" hole from the rear bottom of that reservoir to the bottom of where the bearing cup is. So now when I run the lathe, the oil is pumped out of the reservoir and circulates with the bearing (which was unintended). When running the sight glass shows the level has dropped to nothing on the sight glass. Your lathe probably did not have the design or manufacturing error, so the bearings were working as an oil pump.

Click for full size images

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks