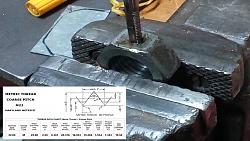

For this build used two old used shock absorber bottles into one pair of a parallel arrangement and an angle grinder Ø115mm.

The grinder's traveling is 175mm.

Before proceed to anything I had remove the hydraulic fluid from pressure tubes.

Over the base at the left side I made a vise for straight cuts as well and a sliding cutting guide at the right side for straight cuts at zero degrees and bevel cuts at 45 degrees.

My English is too poor to describe the whole process of this project and I will need too many hours for translating.

So I will use some sort descriptions and of course I will answer at all questions to everyone.

So please forgive me.

Part1

The two shock absorber bottles into one pair of a parallel arrangement.

Pivot and bousings.

Part2

Bench - Βase

Mounting and leveling at the base the arrangement with the shock absorber bottles

Vise

Part3

Cutting Guide Zero & 45 Degrees

Part4

Different cuts (straight cuts 0° and bevel cuts 45°) with different materials from 3mm to 10mm thick as well as tube 20x40x2mm.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks