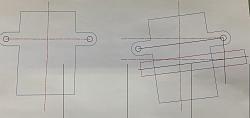

A mill cannot machine true if the fixed jaw on the vise is not aligned to the X-axis. Here is a procedure to do the alignment plus background on what you can expect for accuracy. A video is included.

If you are interested, please, click here.

Your comments are welcome. All of us are smarter than any one of us.

Thanks,

Rick

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks