I built a spring loaded platform for my K40 laser.

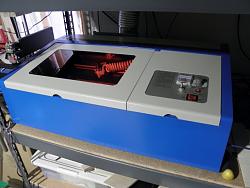

First a little background. K40 lasers are cheap CO2 laser cutter/engravers that are available on e-bay, amazon and a few other sources for around $500. They are functional but lack many features. Below is a picture of my K40 to give a point of reference as to what this platform is installed inside of.

The purpose of the platform is to allow for the use of different thicknesses of material while maintaining the correct distance to the surface of the material so the laser is always focused at the material surface. I achieve this by having springs push the platform up to a hard stop formed by a piece of angle aluminum. When an item is placed on the platform a small portion of the material is pushed under the hard stop surface. Then the springs push the material up until the top surface of the material is positioned at the laser focus height by the hard stop.

Here is a picture of the adjustable bed used with expanded metal mesh

Here is a picture of the adjustable bed used with two rods to minimize the support area.

This is a picture of the parts from one side of the bed support.

Below is a video showing how it works and all of the parts. A few more details are posted in a blog post here: Spring Loaded K40 Laser Platform

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks