Originally Posted by

Workshopshed

Hi Rick,

an interesting idea and definitely worth investigating. I'd be concerned that dirt and other containments on the screw might affect the reliability.

I've seen variations on this using a digital readout to get the absolute position of the moving parts. You might also be able to look at the current flowing through the motor, with a low load that could be less than when the motor is actually moving the parts.

Also perhaps a load sensor in the thrust bearings of the lead screw might work?

Good luck with your experiments.

Andy

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

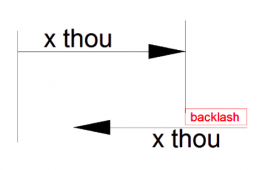

) for some time now and this post has inspired me to chime in my 2 cents worth. The idea you have for the adaptive system is quite good but has its limitations as you point out. The other thing that came to mind is if you needed to perform an operation at a float point then your system would automatically push or pull to the no backlash point although by your measuring seems to rest in the bottom half. Also steppers are kind of a pain in that they tend to fall off position under load, which can lead to other issues, so I tend to lean toward servos. Using some kind of quadrature add-on system might give some advantage but adds to the complexity and interface although I believe M3 has a quadrature interface option. The real issue to me is all the variables in the screw, nut, end play, concentricity, bow, etc. and it occurred to me that maybe approaching this more from the mechanical aspects (as you have been) would give you more leverage on the tolerance stack.

) for some time now and this post has inspired me to chime in my 2 cents worth. The idea you have for the adaptive system is quite good but has its limitations as you point out. The other thing that came to mind is if you needed to perform an operation at a float point then your system would automatically push or pull to the no backlash point although by your measuring seems to rest in the bottom half. Also steppers are kind of a pain in that they tend to fall off position under load, which can lead to other issues, so I tend to lean toward servos. Using some kind of quadrature add-on system might give some advantage but adds to the complexity and interface although I believe M3 has a quadrature interface option. The real issue to me is all the variables in the screw, nut, end play, concentricity, bow, etc. and it occurred to me that maybe approaching this more from the mechanical aspects (as you have been) would give you more leverage on the tolerance stack.

Bookmarks