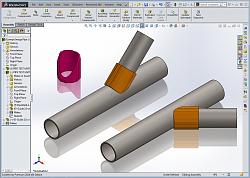

2.51" OD Pipe welded at 45 Degrees onto a 2.90" OD Pipe.

I had a Pipe (2.90" OD & 2.52" ID) and wanted to weld another pipe (2.52 OD & 2.27 ID) onto it at 45 degrees.

Could have used a pipe wrap or other items but decided to 3D-Print an ABS Plastic 'Scribe Guide'.

When I first tested my 3D-Printer I was shocked how accurate the dimensions of the final items... Since then I have used it constantly for testing part fit-ups before machining the actual parts out of metal.

The 'Scribe Guide' is designed so I know when cut line is drawn on the 2.52" OD pipe the other back end of the plastic guide is exactly 4" from the center line of the larger pipe.

I wanted the smaller 45 degree pipe to be 9" off the center line of the larger pipe ... so I measured an extra 5 inches back from the back end of the 3D-Printed guide and marked it for a straight cut in the horizontal band-saw.

After drawing up the 45 degree 'Scribe Guide' in SolidWorks CAD Software ... then 3D-Printed it.

It took a little over 2 hours to 3D-Print but after pressing the PRINT button I didn't have to watch it or do anything else... I just walked way and worked on another project and came back a few hours later and it was completely done ready to use. (Hands-off means can use time to work on other projects ... or Sleep *grin*)

Many times I will start a 3D-Print and go to bed and wake up in the morning and the 3D-Printed item is finished.

(No Smell or No heat other that protected printing tip when 3D-Printing ... I keep mine in the spare bedroom on a wood dresser)

Use an AFINIA 3D-Printer ~ https://store.afinia.com

Drew on the pipe using a Sharpie marker and cut it will a metal saw but could have used an Oxy/Acet torch, or plasma-cutter ...

The same plastic 'Scribe Guide' can be used to draw on the larger pipe the inner hole cutout area by drawing a line inside the guide with it placed on the larger pipe.

Probably not my best looking weld but decided to weld a little and let it cool and then welded a little more and let it cool... Wanted to keep the longer pipe from warping from too much heat all at once on one side.

The 3D-Printer is very helpful for making unusual shaped parts that don't have a lot of stress on them like the DRO mounts for my new Milling Machine ... This pipe guide also worked very well.

CHEERS!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks