Built some new metal shelves for the Lathe area and needed a way to hold the new Lathe’s (Morse Taper) MT-3 tooling secure.

3D-printed ABS plastic inserts seemed like a solution …

I could have used rubber Grommets ... but where is the fun in that?

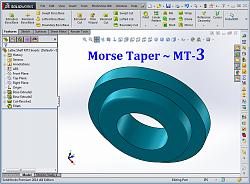

Designed the ABS plastic inserts using SolidWorks CAD Software ~ The inner hole has the same 1.4377 degree taper from center line as the MT-3 Tooling.

Converted the SolidWorks CAD file into a 3D-Printing STL file and started the 3D-Printer ...

The finished 3D-Printed ABS plastic inserts pressed into the 1.5″ diameter holes I cut in the sheet metal shelf using a hole-saw on the drill press.

Once the MT-3 Tooling was secure in the 3D-Printed inserts … Decided to make a ‘quick access’ 3D-Printed ‘Cup Holder’ for the drill chuck key.

Found some scrap 5/8″ round-stock steel and used the lathe to bore a hole in it the same size as the chuck key handle diameter … Then pressed the chuck key into the round stock creating a comfortable handle chuck key unit.

Wanted it easy to use the Chuck Key so designed the 3D-Printed ‘Cup Holder’ type design about 1.875″ deep with a loose fitting diameter of 0.700″.

The best part is while I kept working in the Workshop, the 3D-Printer was making the ABS plastic inserts in the house … Felt like getting twice the work done!!

Sometimes the simplest of items can be very helpful.

https://ctmprojectsblog.wordpress.com/about/

... CHEERS!! @MetalDesigner on Twitter

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks