These are knobs for thumbscrews to make it easier to install and remove the change gear cover on my Homier 7x16 Minilathe.

(This stretches the definition of a homemade "tool", but I'm going to have a whole series on mini-lathe stuff so it made sense to put it here too.)

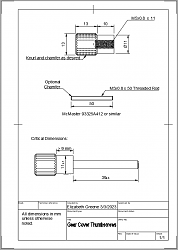

To make these, I printed them in PLA with the threaded hole facing up. This hole has modeled threads, but depending on your printer's tolerances and tuning you may have to drill and tap the holes for M5-0.8. (I did).

Each thumbscrew requires a piece of M5-0.8 threaded rod 50 mm long. McMaster-Carr 93805A636 would work, but I was able to source threaded rod locally at a significantly lower cost (Ace Hardware - Midwest Fastener Brand, 100mm $1.95). The threaded rod is permanently affixed to the handle with Loctite Blue 242. Other adhesives would also work, e.g. epoxy, The 242 is what I had at hand.

Small parts printed with FDM may deform if your printer is too fast to allow sufficient cooling between layers. This is visible in the picture above as a wavy deformation in the print. Reducing the print speed addresses this issue.

A .pdf drawing and the Fusion 360 .f3d files are on my GitHub at https://github.com/ElizabethGreene/M...%20Thumbscrews if you'd like to reproduce this in another material. (Turned brass would be pretty.) If you make one that way, only the last ~10mm of the rod needs to be threaded.

Discussion:

I tried making one of these as one piece in steel (including the threads) and it didn't go well. Holding the round bit below the handle in the chuck I was able to turn down the threaded portion to fit a die, but (as I'm sure you guessed) there was a significant amount of deflection in that loooong skinny bit sticking out so far from the chuck. That diameter (~4.5 mm) is too small to hold a live/dead center though. How would I support that? I have a follow rest, but it's still packed in 20-year-old cosmoline.

Thinking about it now, I guess I could hold the stock with ~10 mm sticking out, turn that down to the diameter to be threaded, then pull out another ~10mm, turn that, pull out more, repeating, but I only have a 3-Jaw and I'd struggle to maintain concentricity. I guess strict concentricity isn't absolutely required, it would just be cosmetic.

Offer:

If you don't have a 3D printer and want a couple, PM me and I'll print you some.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks