re:filling the vial. My choice would be 90% medicinal alcohol. It will take food coloring as a dye, freezing will be non-issue, easily found and handled. Dye somewhat larger quantity than needed with a pinhead to 'spoon' it.

The real trick will be determining what volume is needed for a proper size bubble. Maybe fill it experimentally, hold end shut and horizontal. Once found, up-end and felt-tip mark a graduation on side for later. In regards to filling the tube, my first test would be to submerge it; otherwise a plastic eyedropper.

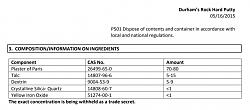

We have a popular epoxy here called J-B Weld, find an equivalent to seal nib.

Sulfur is low melting point but not getting quick even distribution could crack vial. I guess warming it in hot water is possible. I used plaster of paris for my Starrett level.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks