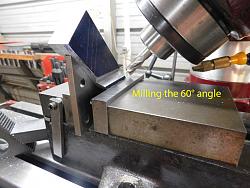

I was making some new locking handles for the table and cross feed on my mill the other day and had a brain storm, these handles I’m making have a locking lever that requires a tapped hole at 30° to the axis of the handles screw, drilling and tapping these holes at that angle is not a problem if you had just the right size v-block with an angle plate under it, they could also be tapped with just an angle plate under them or a dividing head and several other ways, the jaws on the mill vise are only 1-3/8” tall so it was a toss up to make just the right size v-block with an angle plate under it or just make a v-block with some common angles machined into it, so I decided to go with a v-block with three different angles milled into both faces, one side of the v-block has a 30° angle milled into it and the other side has a 45° and a 60°, the v-block is ground to the same height as the jaws on my vise making it easy to setup, the degree marks are clearly stamped to their corresponding angles, I had thought about making one of these some time ago but never got around to it nor had I the need for it until now, just another little quick setup fixture.

This block is made from O-1 steel hardened and precision ground flat, square and parallel on all six sides, the vees were then precision ground true to the adjacent sides.

I have included some photos of the machining and grinding processes and some photos of the block being used.

As always thanks for looking and happy machining

Doug

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks