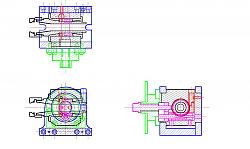

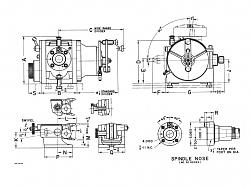

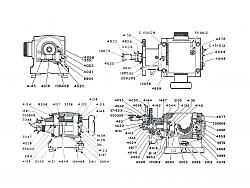

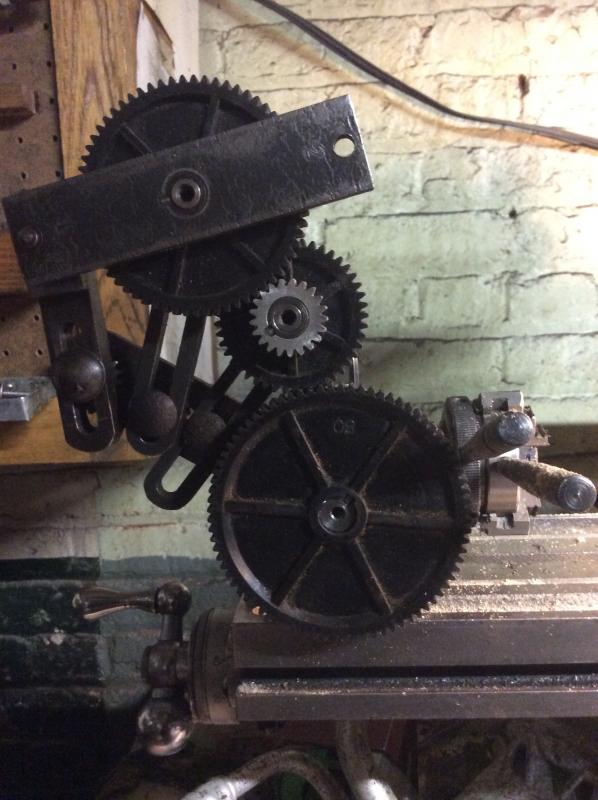

This dividing head replaces a more delicate one I made from Unimat parts. It combines features from Hardinge and Cincinnati dividing heads but is simpler and a lot smaller.

Like those, it indexes indirectly, in this case with a 40:1 ratio, or directly by disengaging the worm, and it tilts from about -5° to 90°. It has a brake to lock the spindle, and works with a small adjustable tailstock.

It’s not universal - the hub for dividing plates is stationary. I mostly just use combinations of change gears to make divisions, though, and figured it will be easier to add stepper motor control than to make tiny parts for a differential feature I might never use.

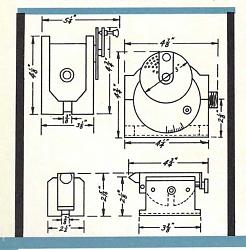

It’s about 3 x 3 x 3”. The spindle nose is threaded M22-1.5, with a 16° included taper for ER-16 collets, and has a 3/8” bore. The spindle is prehardened medium carbon steel, and the bearings, worm gear and brake sleeve are bronze; the body from cast iron bar stock, and most of the base is made from a piece of heavy angle iron.

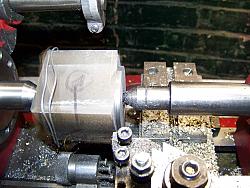

Turning the hubs between centers, and cutting a timing belt pulley to convert it to stepper drive

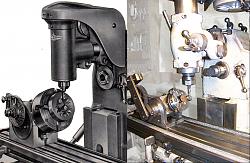

Cincinnati, and Hardinge

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks