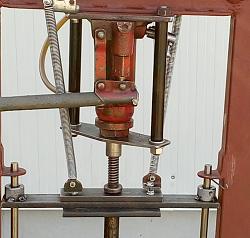

Finishing simple 20 ton press, very traditional design.

That was asked.

Inverting jack is made same way than this video:

Container is made from alumine gas bottle. ( Tire repairing foam bottle )

Jack moves sideways 350mm

"Rails" are made from pipes and connected to frame with nuts. Loose connectio between nuts and pipe, so in use javk leans against frame.

Sorry about blurry images, better ones when the build is ready.

Thanks for checking this out.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks