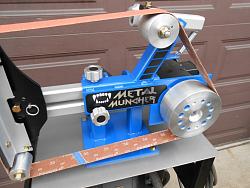

It's big, it's BLUE and it has an appetite for ferrous metal! It's the Metal Muncher! (sorry, I had to)

Thought I'd never get this done! I've been working on this since March 1st and putting in some long days to get here! It's been a ton of fun but a heck of a lot of hard work too! It's also the most expensive project I've ever built but considering commercial belt grinders of this quality run $2,500 - $3,000 that does take some of the sting away. (Sorry, I have not added everything up yet)

This is a 2 x 72 Belt Grinder built from plans that I purchased online and while I kept mostly to the specs, I did make a few tweaks here and there. Will be making modifications and upgrades as I see the need.

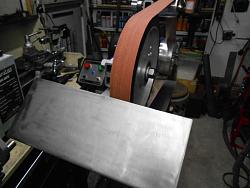

Like most things in my life, I like to do as much myself as possible. I opted to make my own wheels instead of buying them. I already had the 2 & 3 inch round aluminum stock and the bearings so a quick search on ebay turned up the 7 inch slab I needed for the drive wheel. Let me tell ya, working with a 7 inch chunk in a 6 x 4 band saw and a 7 x 16 metal lathe does present some difficulties but I eventually won the battle.To do it over, I would just buy the drive wheel already made, it was the most challenging. I didn't save any money on that one but I guess I got some good experience and bragging rights anyway.

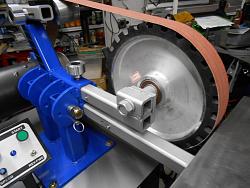

I made all my own knobs. The material I had already and this way I got to create my own design. All made from 6061 aluminum stock.

I did go with the 2HP Ironhorse motor that was suggested in the plans but found a VFD that was about $100 cheaper than the one they used. I'm really happy with the WEG VFD that I chose, it's crazy customizable!

To keep the VFD which is the most valuable part out of the dust, I mounted it under the shelf to the rear. I made a seperate control panel and all controls are up top at fingers reach. It has Forward & Reverse as well as speed control.

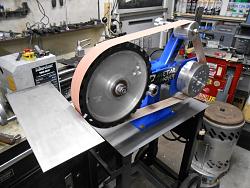

This unit works both vertical and horizontal and is STRONG!!! It's also very heavy but that's a good thing in belt grinders. lol

The cart (not part of the plans) I designed myself and I kept it as small as possible due to space limitations. (I need a bigger garage!!)

It's made of 2 inch & 1.5 inch 16ga tube and has heavy duty rubber front casters and solid 10 inch rubber rear tires.

Since I needed a place to store my small shop vac anyway, this was the perfect place for it! I will most likely add some type of dust control to the belt grinder so I'm half way there already. I designed this so I can very easily pull the vacuum out for jobs around the garage and cleaning my cars.

Specifications:

Verticle / Horizontal sanding positions

Forward / Reverse / Adjustable speed

VFD: Weg CFW-300

Motor: Ironhorse 2HP AC Induction 220 volt 3 phase motor 3600rpm, 5/8 keyed shaft

Switch panel: I designed and fabricated the control box myself and used some switches I had on hand and a few I bought on ebay for this project.

7" x 2-3/4" inch drive wheel.

3" x 2-3/4" tracking wheel with a 1 degree crown.

2" x 2-1/2" platen wheels.

Bearings: R8ZZ

Hardware: Grade 8

Graphics: I did all the vinyl graphics myself using a Cricut cutting machine.

Colors: Deep Gloss Blue Rustoleum, Metallic Black Rustoleum, Hammered Silver Rustoleum and Flat Aluminum.

Weight: HEAVY!

Future plans:

Adding a 12 inch rubber contact wheel that can used instead of the flat platen.

Some form of dust collection (although this will only be used outside my garage)

A water tank to dip parts when they get too hot to hold.

A surface grinder attachment that I will build myself in the near future.

Small wheel attachment.

Radius attachment.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks