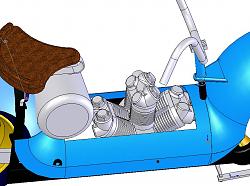

The Engine

After making new bushes and shafts for the crankshaft and rods I was pleasantly surprised when the gudgeon pins slid though both conrod eyes when fitted to the big end.

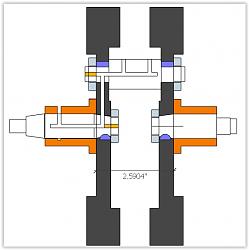

The whole crankshaft assy however is real problem to get running true, the tapers in the flywheels are clapped out and not seating properly due I think to the engine being run with loose seatings (everything is of bolt up construction). Best I can achieve so far is a .005” TIR error on both main shafts which is no good and not helped by a 3.5" stroke. My only option is to skim the tapers in the flywheels to reclaim them, fortunately they will just fit on my home made faceplate. I cannot afford to remake the shafts again as I no longer have access to tool room equipment i.e hardening and grinding. In a last ditch attempt to save this potentially scrap engine I decided to grind the inner flywheel conrod faces with a milling spindle and a diamond speed pin, this was successful as the fly wheels are truly spaced when assembled on the crankpin. This has brought the run out down to .0004" tir which is the best I can do and for all I know is as good as the original. This has taken around forty hours so far and it is pure stubbornness that has kept me going. Next the main bearings and case assembly.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks