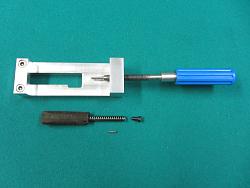

Hello, first off I will never claim to be a machinist or a gunsmith. I enjoy making things myself. A thanks to all who post homemade tools and projects. Some of the tools are way beyond my skill level. I do most of my own work on my 1911 pistols. This tool is for holding the mainspring housing while replacing the spring or simply polishing the spring bore for a smoother action. The old school way was to just pound a nail in the workbench and while depressing the spring and push the retaining pin out. I did that for years. Works great when you are young. Now I'm an old geezer and it's a royal pain to change. There are tools like this one out there, but I didn't like them. One of the issues is the spring bore is on a 5-deg. angle. The tools I looked at the depressor was parallel to the tool. When using it the spring housing would bow up and you still had to hold it down. When I made this tool the depressor is the same angle as the spring and its hands free to use. I can shake the tool any direction and the part does not budge. I made this with all scrap stock, an old nut driver, threaded rod and a broken drill bit for a pin to push the spring cap. When using this tool it forces the part to the rear and actually clamps it in place. One of the pictures shows a gauge pin in place to see the angle its actually on. Thanks. Mr Mikey.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks