Not sure if this is the right forum to put this but here goes. I picked up a 15" Delta planer cheap at auction last December. I new the outfeed roll had some deep grooves worn into it and the adjusting hand wheel had a lot of sloppy play in it so last January I decided to dis-mantel it and see what other problems I could find before using it.

As received after a clean up.

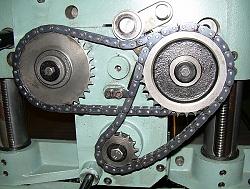

The inside indicated a lot of hard use.

One thickness adjusting nut was broken.

And here is an indication of what caused all the problems, a good dent in the chip breaker, indicating that a piece of wood with steel in it had been fed into the planer. The second pic is the chipbreaker after straightening and cleaning.

The reason the adjustment wheel was so sloppy was the adjustment shaft was worn where it was supported by the top bushing and the bushing had some were as well, after my parts order arrived I bored the bushing to accept a bronze bush and bored the bronze bush to accept the new shaft. My reasoning being the bronze bush will not wear the expensive adjusting shaft (screw) and the bronze bush will be easy to replace in the future.

The next pic. is the new outfeed roll with new bushings and the old one.

The outboard cutter head bearing was running dry (on the left) so I replaced it with a snowmachine bearing, double lip seals and rated for 10,000 RPM.

Continued in next post.

Carlos B

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks