Hi All

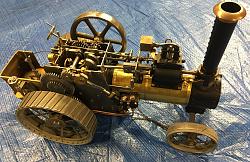

Over the last few days I have decided to set a new years resolution and finish my 1" scale traction engine which I started in 1985. The engine is almost finished with only a few jobs such as the plumbing, fire grate and coal bunker and a few other minor jobs. It will then be taken apart for painting.

Over the last few days I have made the boiler cladding and boiler straps. My home made bead roller had a couple of dies made to create a joggle along the edge of the brass cladding to ensure a nice fit.

http://homemadetools.net/forum/bead-roller-75870

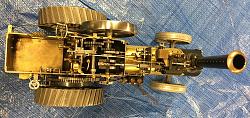

The photos of the engine below has had a few items removed such as the water pump and steering so the cladding could be checked for clearance of the cylinder block, spectacle plate and the water pump. The cladding was rolled on my newly refurbished slip rollers

Sheet metal rollers

So I am starting to reap the benefits of the bead roller and the slip rollers didn't need a good clean before using.

engine needing a little TLC

showing motion gear

Boiler bands riveted and silver soldered ends. These took an incredible four and a half hours to make

Cladding with cut outs. I made a cardboard template to ensure the cutouts would fit the boiler. Trial fitted to a 2,5" tube with wooden insulation material to create the correct diameter of boiler.

Joggle dies to 0,5mm set

Thank you for taking a look at one of my many projects that need finishing.

The Home Engineer

Happy new year to all

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks