Hi,

I recently got the opportunity to purchase for a good price a batch of M33x3.5 nuts, which happen to be the thread of most of the European lathe spindles.

There is a lot of possibilities with these nuts, here are a couple of examples :

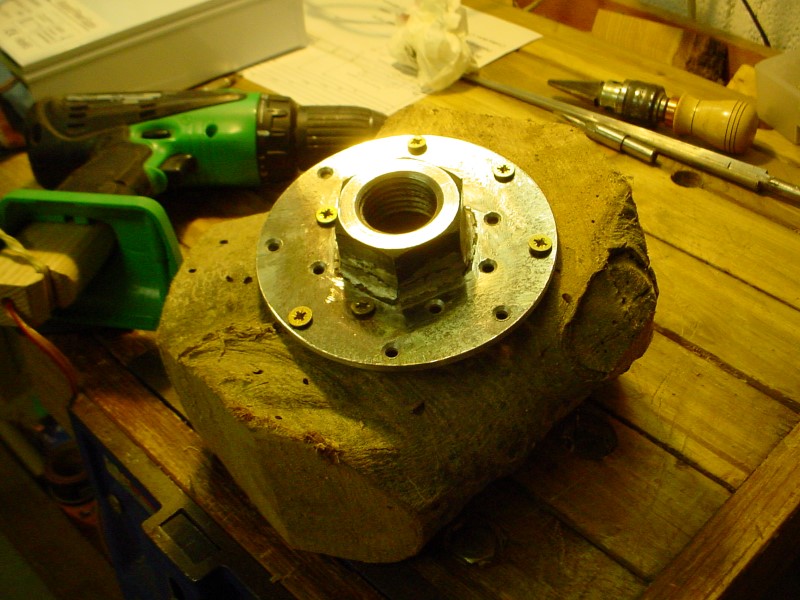

First example is a face plate.

The nut is welded to a steel plate, then mounted on the metal lathe and the plate is then trued up.

The holes are drilled afterwards.

Before welding, I had trued the face of the nut on the lathe (I have an M33 spindle that can be mounted on my metal lathe chuck)

And here we go:

Here, as I haven't got any 33mm spanner to unlock the nut after the turning (and dit not make one yet), I use this rubber band tool which appears to be very powerful.

I have often some difficulties to source plates of metal. Here is an idea ... (this is not what I used for the above example).

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks