Hi,

Here is something I made during the last week-end.

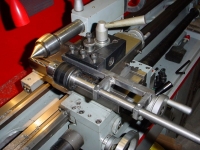

It is a system for drilling transversely a workpiece, hold on the lathe chuck, without removing it.

I saw this idea somewhere (can't remember where), but it was for the wood lathe.

My first need was for the metal lathe, so I first did that, and then, I will show the adaptation for the wood lathe.

Here are a few pictures :

It is for the moment a low tech system, so no bearing or bronze bushing. It is made of a standard "Jacobs" chuck that I installed at the end of a long 12mm shaft. (trying to keep as much as possible aligned).

Then the shaft passes through two holes made in a little frame, itself hold in the QCTP of the lathe.

See the picture below (setting up the height of the tool with the live center point) :

As the chuck has a certain length + the length of the drill, I made this shape for the frame, so that the chuck can be pulled enough away from the piece.

As there is no special bearing or bushing, my solution was to simply drill two small holes where the the shaft passes through the frame, in order to put a drop of oil on each hole :

The shaft is powered with the hand electric drill :

Here is the first hole I drilled with it : it is for making a depth stop ring for the tool itself ! (some kind of egg and chicken story, the tool that maked the tool ...)

This is low tech, but with the drop of oil, it is far good enough for me, for the occasional use I will make of that tool. (and there is room for enhancement, if need be)

Next topic will be the same, but for the wood lathe.

Christophe

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks