Hi,

I needed something to index the spindle of my metal lathe, and I decided to build it, adding the crank feature. I wanted something not too much intrusive and that would be quickly mounted / unmounted as needed.

Here is what I came up with :

And here is how I did it :

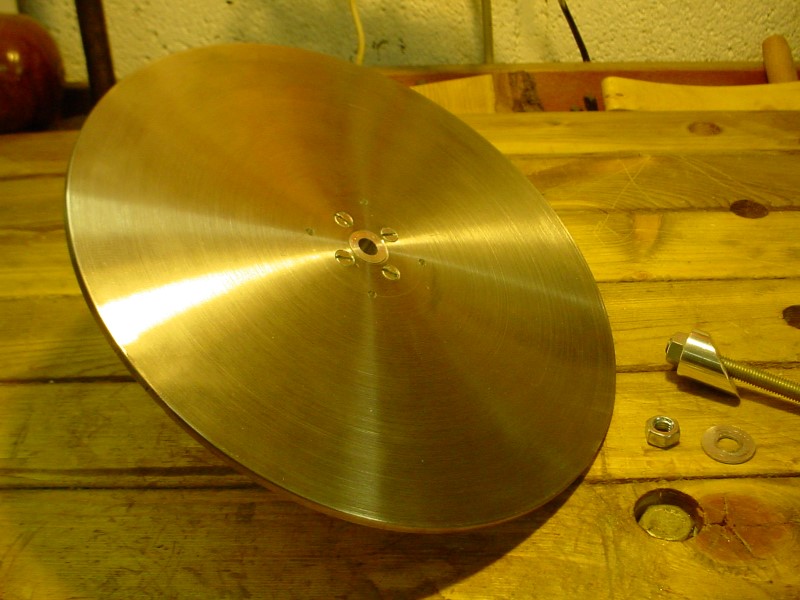

First the plate, continuing on my idea to source metal in the kitchen utensils, it is made from an induction interface plate. I initially thought it would have been made of plain stainless steel, but I discovered when drilling through it that it is actually principally made of aluminum, coated with stainless steel sheets on both sides. Anyway, this is good enough for me, it is 5mm thick.

The shaft is turned out of aluminum round stock, and will be inserted in the spindle (21 mm on that side).

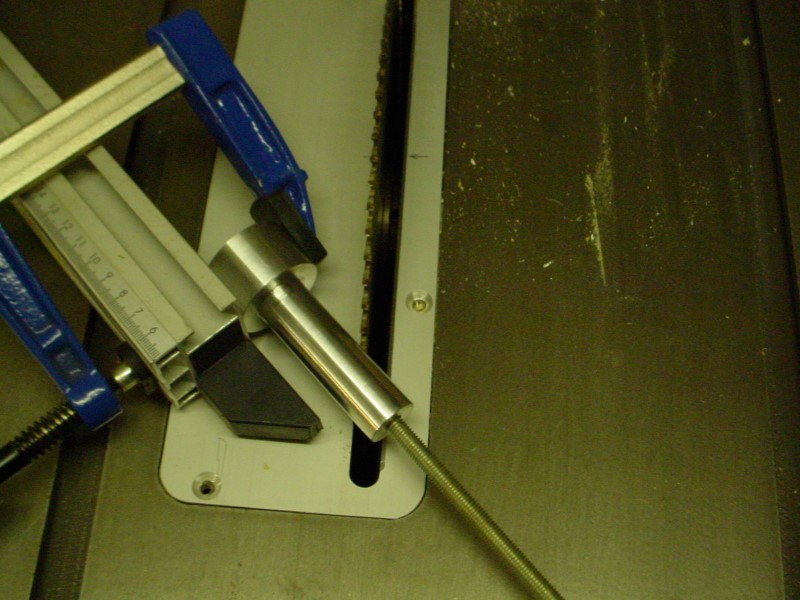

The shaft is cut at 45° using the table saw. Wood cutting tools work well for aluminum.

I don't remember who gave me this idea for locking the shaft in the spindle, I think it's here, maybe Paul Jones.

It works very well and is really much easier to make than an expending system.

The plate is screwed on the shoulders of the shaft.

On the right you can see the beveled bottom part of the shaft. The inside bore is threaded and a piece of threaded rod will be used to pull it and lock it.

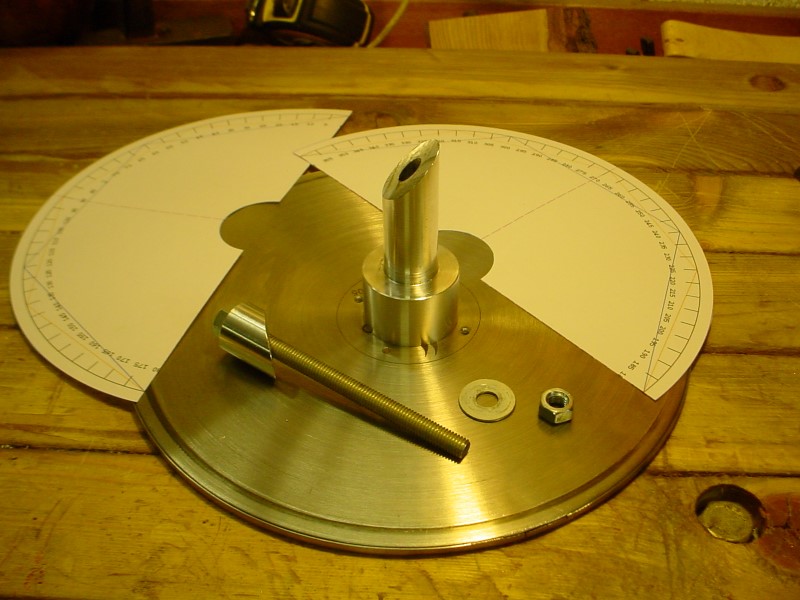

For drilling accurately the indexing holes, I drew a two pieces template with my

CAD software.

It was initially planned only to be a template but I left it glued on the plate actually and varnished it to protect it from dirt.

The crank knob, wood turned out of beech. I inserted a brass sleeve in it to ease the rotation of the knob around the screw.

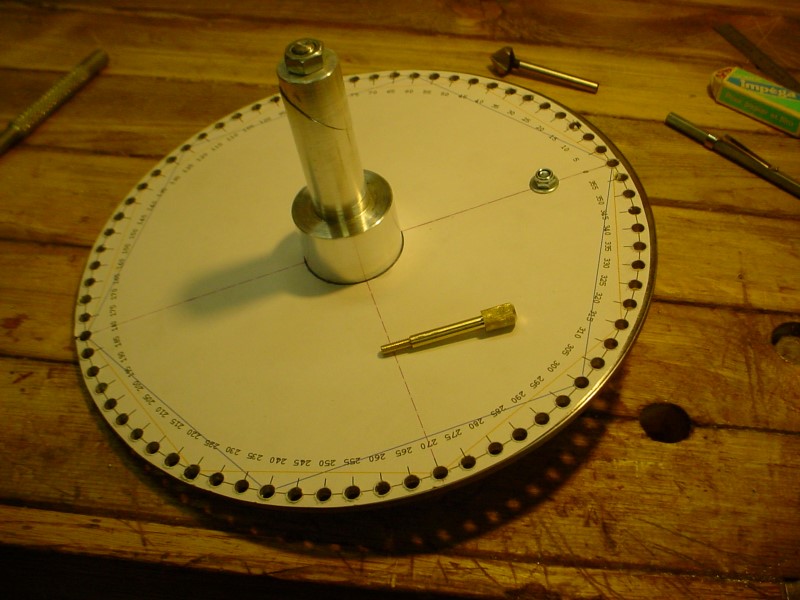

Finished Verso. The brass pin will be inserted in a small block of steel screwed on the lathe body.

The tip is threaded M4 and the shaft has a 5mm diameter.

Finished Recto :

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks