Here are a couple of stitching awls I have made, build from scratch, blade and handle.

The two awls I have made are the two at the front, the one at the back is a vintage commercial one, for heavy duty leather work.

One of the handles is made of ash, and the other from ebony.

Here is how the blades are made, starting from a hardened concrete nail :

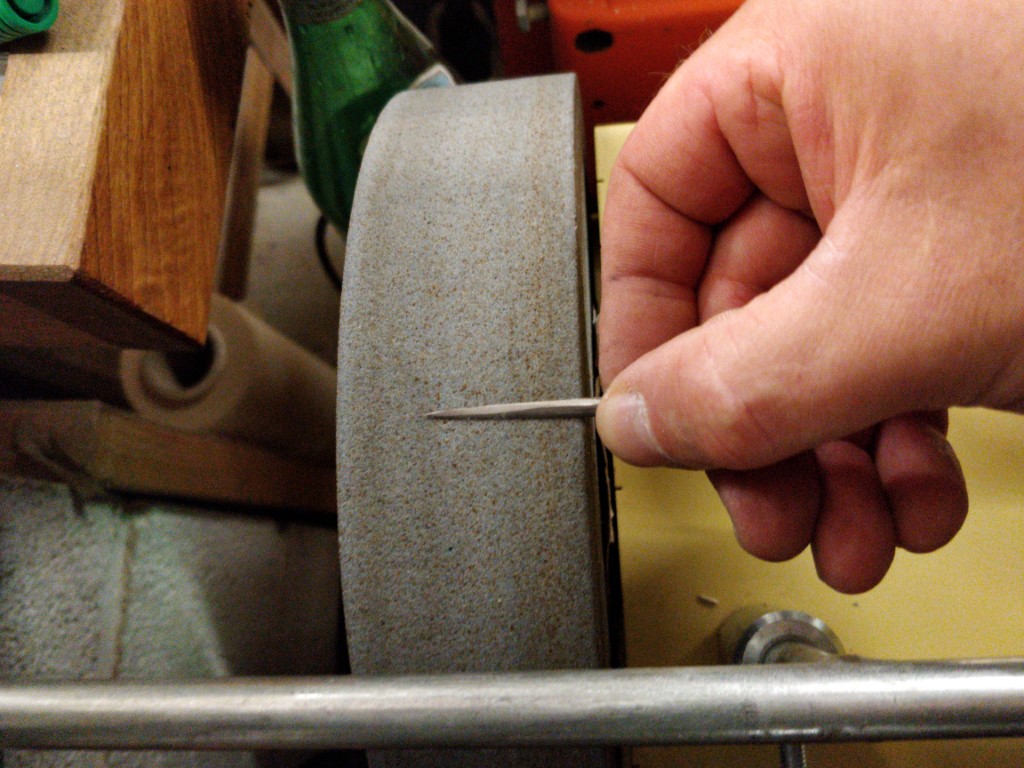

First, roughing out with a high speed grinder (I frequently dip the blade in a jar of water before it looses its temper).

I grind four faces, in a kind of sword shape.

I made a small batch blades of different width

Then I switch to the wet slow speed grinder, and I refine the edges. The tip is quite flat and cutting, and the body has a diamond shape, more intended to expand the hole than to cut it.

And here is the mounted awl, in the ebony handle. The blade is carefully honed on a strop, it must cut leather like butter.

And here is how it is used, with the stitching clamp I will show next time.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks