Here I am turning a batch of pad cups for Keys, for woodwind instruments. It's made of nickel silver.

It can be shaped out of metal sheet, but here, as I had a rod with the proper diameter, I decided to go machining them on the lathe.

It's 12mm in OD, and rough cut at 2.5mm in depth.

One face has a pointed head, and the other face needs to be hollowed to make room for the felt pad.

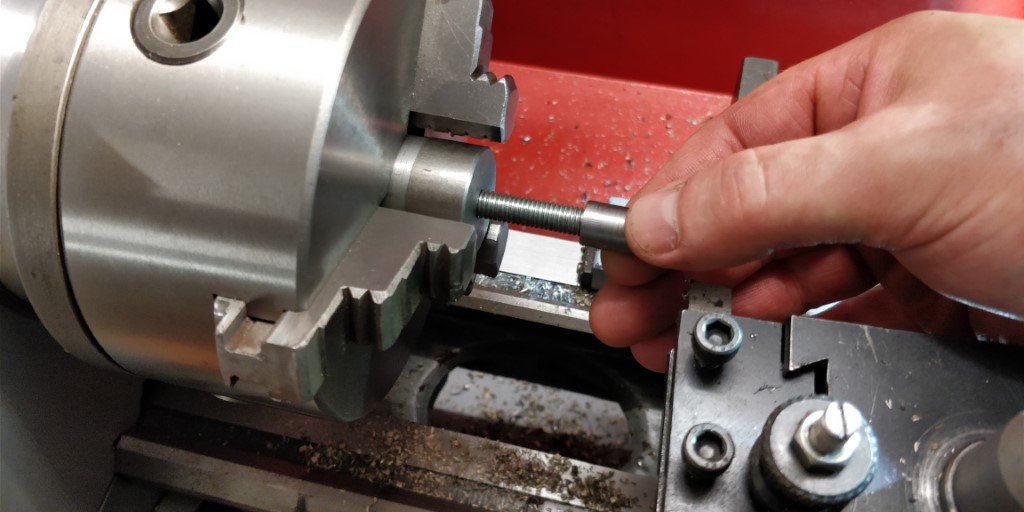

I needed to find a way to chuck accurately these little odd shape pieces in a way that could allow some repetitive operations.

So I decided to do something I have had in mind for a long time, which is a depth stop for my chuck.

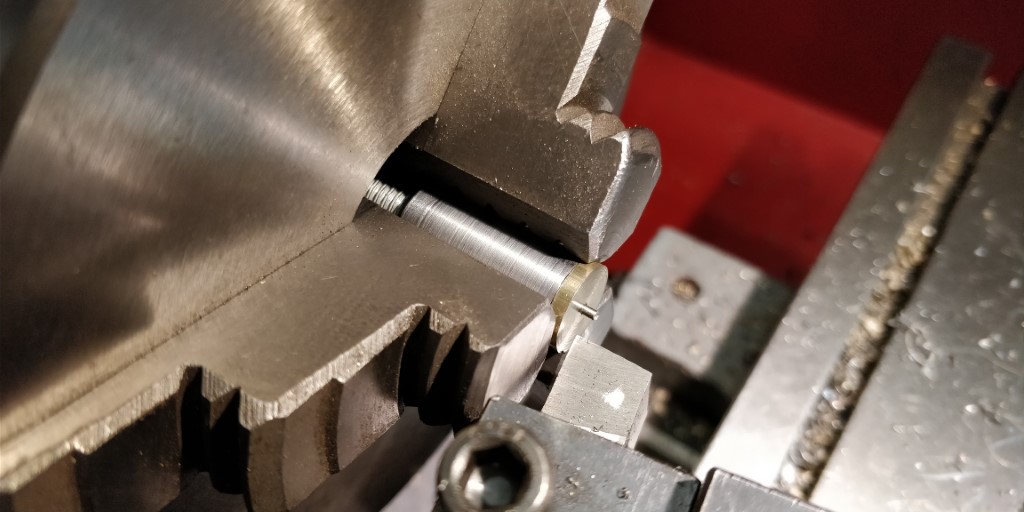

The first picture shows the idea.

My chuck as, just behind the jaws, a 30mm diameter chamber before it touches the spindle plate. End there is yet an adaptative plate between them, with the same 30mm ID.

So the idea was to make a kind of inner core that would fit this chamber, and would be able to hold a piece of threaded rod right along the axis, that could protrude between the jaws, serving as a depth stop.

Additionally, here, as my pieces had an odd shape, I made a small negative head, screwed at the end of my depth stop, so that my workpieces are just chucked at the right depth and well aligned.

The diameter of this stop is arranged to be just a little smaller than the diameter of the workpiece in order to get a proper grip on the piece.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks