While working on a new tool to be posted in the forum I came to a point and discovered I didn’t have a way to do my next step, so that put the brakes on that project for a few days, I want get into details about the tool I was making just about the tool I have to make to complete that tool.Angle Dresser

95% of all the tools I make are finished on the surface grinder, surface grinders leave a beautiful finish and you can work with in a gnats asz, I’ve always been able to setup my work for grinding on a magnetic chuck, parallels, blocks, tool makers vice, or a fixture of some kind, well this time I couldn’t set the part up at a 45° angle on the grinder due to its size, so the only way to grind the 45° angle I needed was to make a tool that would dress the side of the surface grinder wheel at 45°, shops I worked in over my years had an angle and radius dressers, those things can cost you an arm and a leg, I don’t need the radius dressing capability just the angle dressing feature, so over the weekend I came up with this design.

I wanted to make this tool simple and easy to use; this angle dresser does not have pins set at a certain center distance like a sine bar or a sine plate that require the use of gage blocks (which I have), all Iuse is a simple 45° angle plate to set my angle and lock it, most common angles can be readily set using any angle plate.

I make most all of my tools from 4140 steel and heat treat prior to grinding, I didn’t have a couple of sizes of 4140 that I needed so I made the entire unit from 1018, I was in a hurry so I just made it from mild steel which will work just fine, it has been ground all over and looks good and functions as intended.

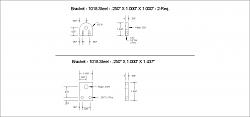

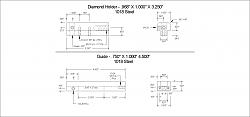

The diamond is guided by a tongue milled on the upper part of the dressers body while the lower body has a slot, making it have sort of like square ways or just plain old tongue and groove, there is an adjustable friction plate mounted underneath the lower body which secures the two body parts from separating yet letting it slide smoothly with just a very slight drag, the diamond is advanced by means of a left hand threaded screw, same as the cross slide on a lathe, I’ll be posting the project that this tool was made to help complete in my next post.

Below you will find some photos of the completed tool along with some photos of the machining process and a video of the tool dressing a 45° angle on the edge of a surface grinding wheel.

As always thanks for looking

And happy machining

Doug

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks